Shaping the Future

of Advanced

Ceramics.

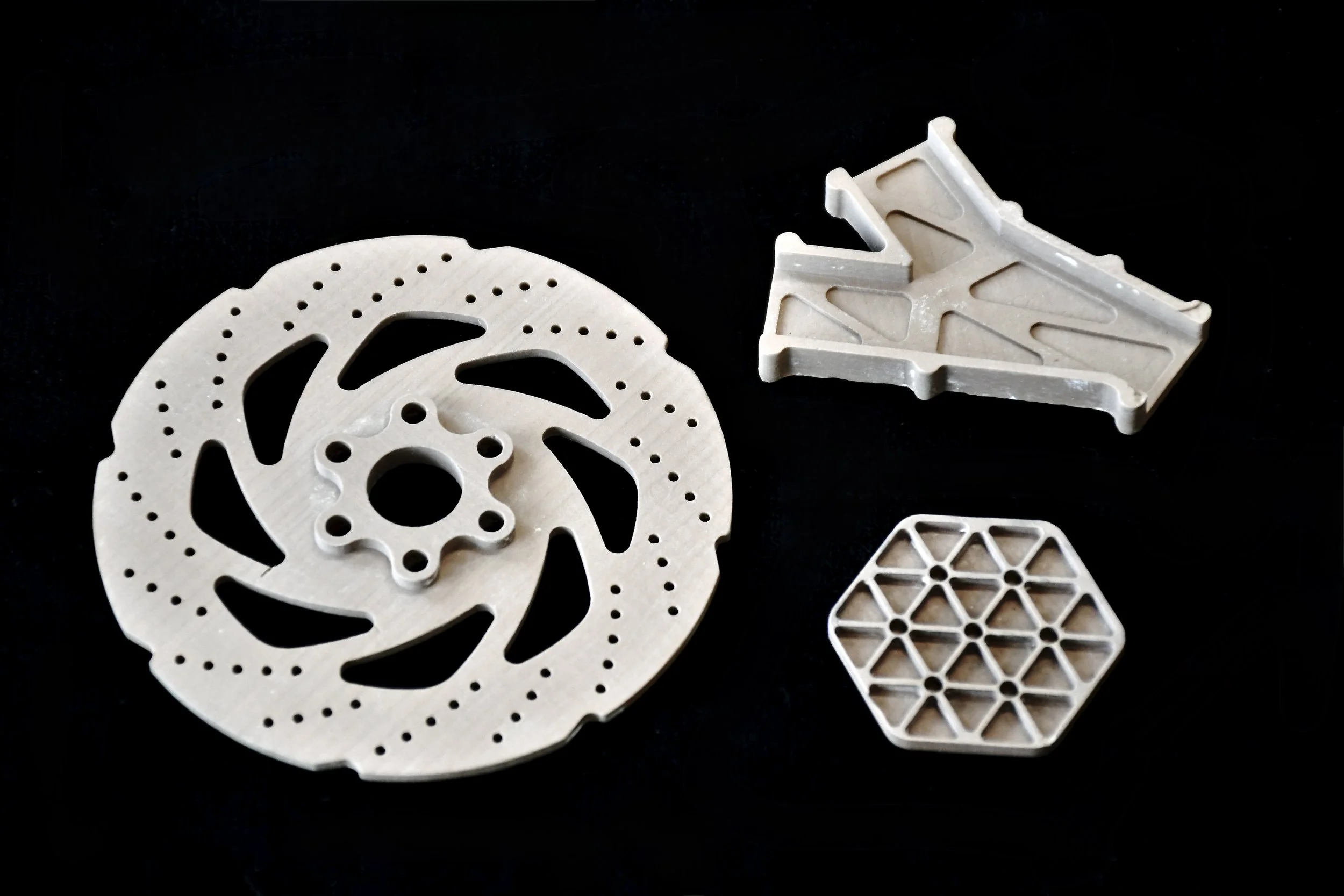

Reimagining ceramic 3D printing

When it comes to ceramics, existing additive manufacturing processes can be limiting; either through build time, quality, material compatibility, or all of the above. Hybrid technology lets us leverage the advantages of near-net AM with the quality of CNC machining.

Compatible with an ever-expanding range of ceramic pastes

Rapid build times

Complex and highly intricate structures

High-precision and low surface roughness

The result?

A machine capable of creating production quality parts in days, not weeks.

Smarter Manufacturing

Reliability is a major issue with 3D printing. Failed prints mean wasted materials, blown deadlines, and frustrated teams. 3D printing's reliability issues have kept it out of critical applications — until now.

Hydra Manufacturing's AI-powered defect detection catches flaws as they happen, not after it's too late.

Our proprietary system doesn't just spot problems — it autonomously fixes them mid-print, eliminating waste and delivering consistent, safety-certified components every time.

Finally, 3D printing you can trust for the parts that matter most.

Introducing CHAMP

CHAMP is our Ceramic Hybrid Additive Manufacturing Platform, integrating additive and subtractive processes to unlock new opportunities.

Freedom of additive manufacturing.

Precision of conventional methods.

All in one machine.